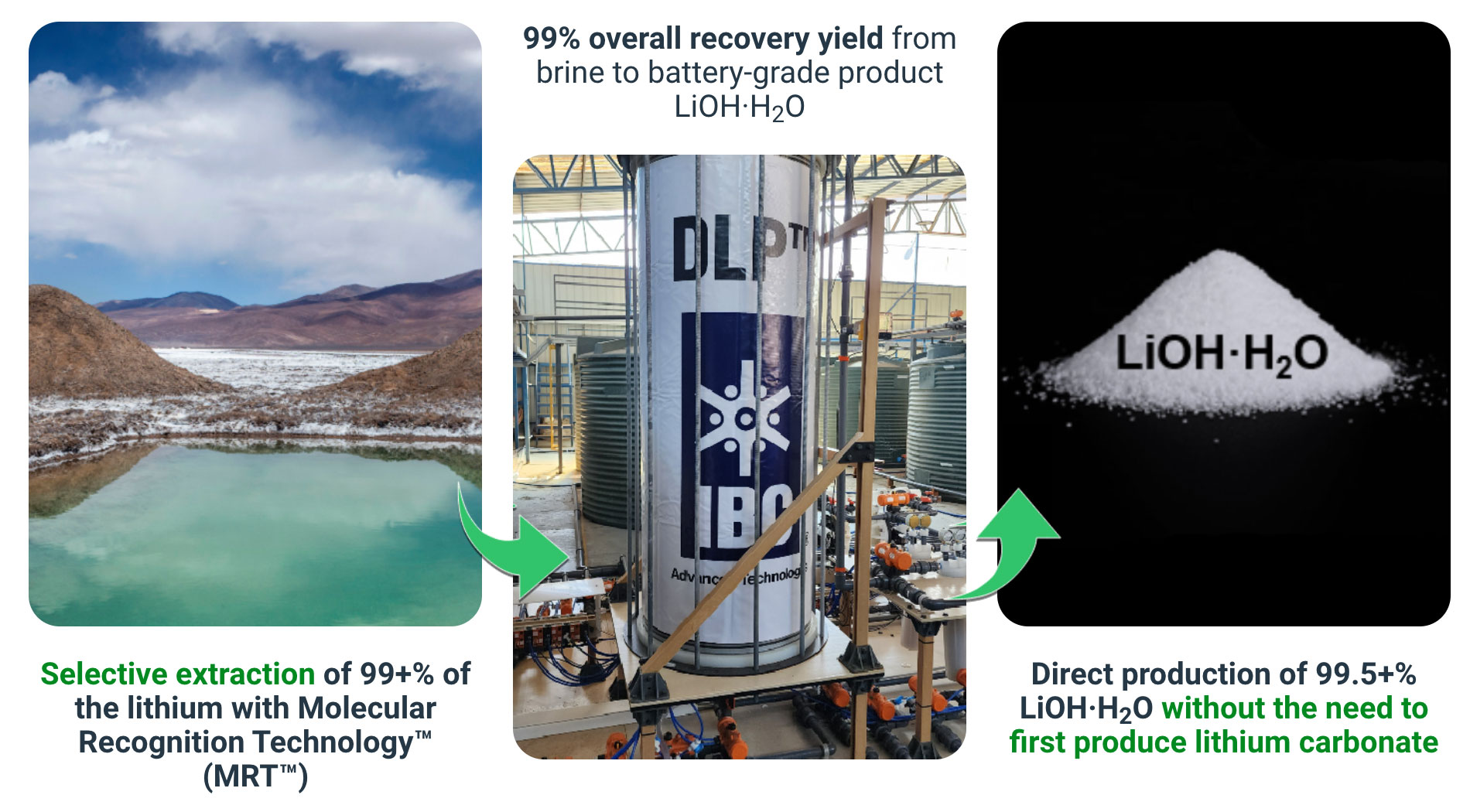

Direct Lithium to Product® (DLP™) Technology

Direct Lithium to Product® (DLP™)

Selective extraction of 99+% of the lithium with Molecular Recognition Technology™ (MRT™)

Selective Lithium Extraction and Production

Selective Lithium Extraction and Production

Sorting through all the direct lithium extraction (DLE) technologies that claim to selectively extract lithium can be exhausting, and to make matters worse, none of them actually produce battery-grade lithium end-products.

At GreenLiT Pure Lithium®, we simplify selective lithium extraction and production of pure lithium end-products. Our Direct Lithium to Product (DLP™) process uses Molecular Recognition Technology™ (MRT™) that is highly selective and extremely efficient. Reusable MRT™ resins selectively extract 99+% of the lithium from brine, resulting in direct production of 99.5+% pure lithium hydroxide monohydrate (LiOH·H2O), without the need to first produce lithium carbonate.

See what our customers are saying in Maricunga Lithium Project, a presentation given by SIMCO Lithium at the 17th Lithium Supply and Battery Raw Materials Conference in June of 2025.

Direct Lithium to Product® (DLP™) vs Direct Lithium Extraction (DLE)

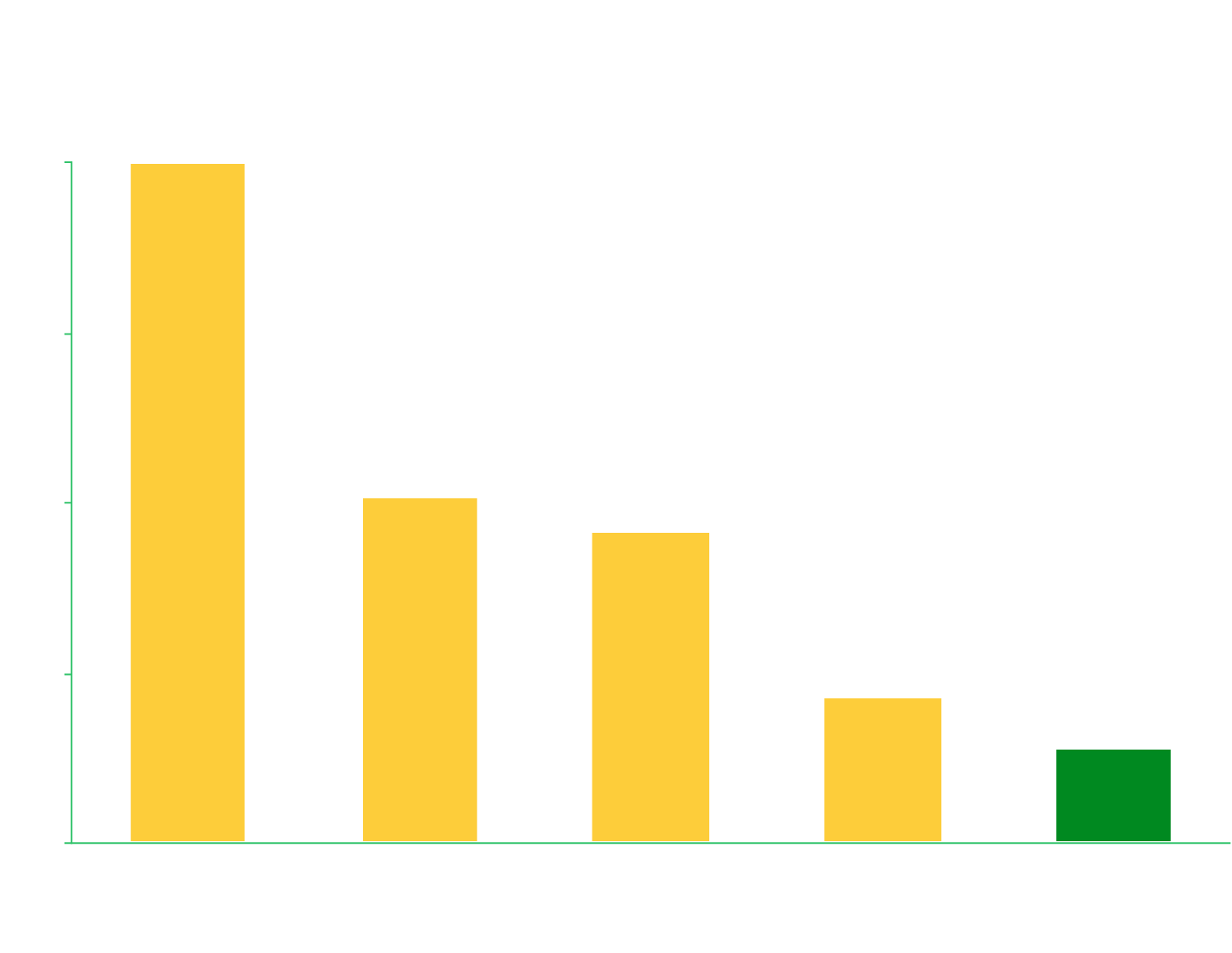

The following results from our large-scale DLP™ pilot plant at Salar de Maricunga in Chile speak for themselves, especially when compared to DLE technologies.

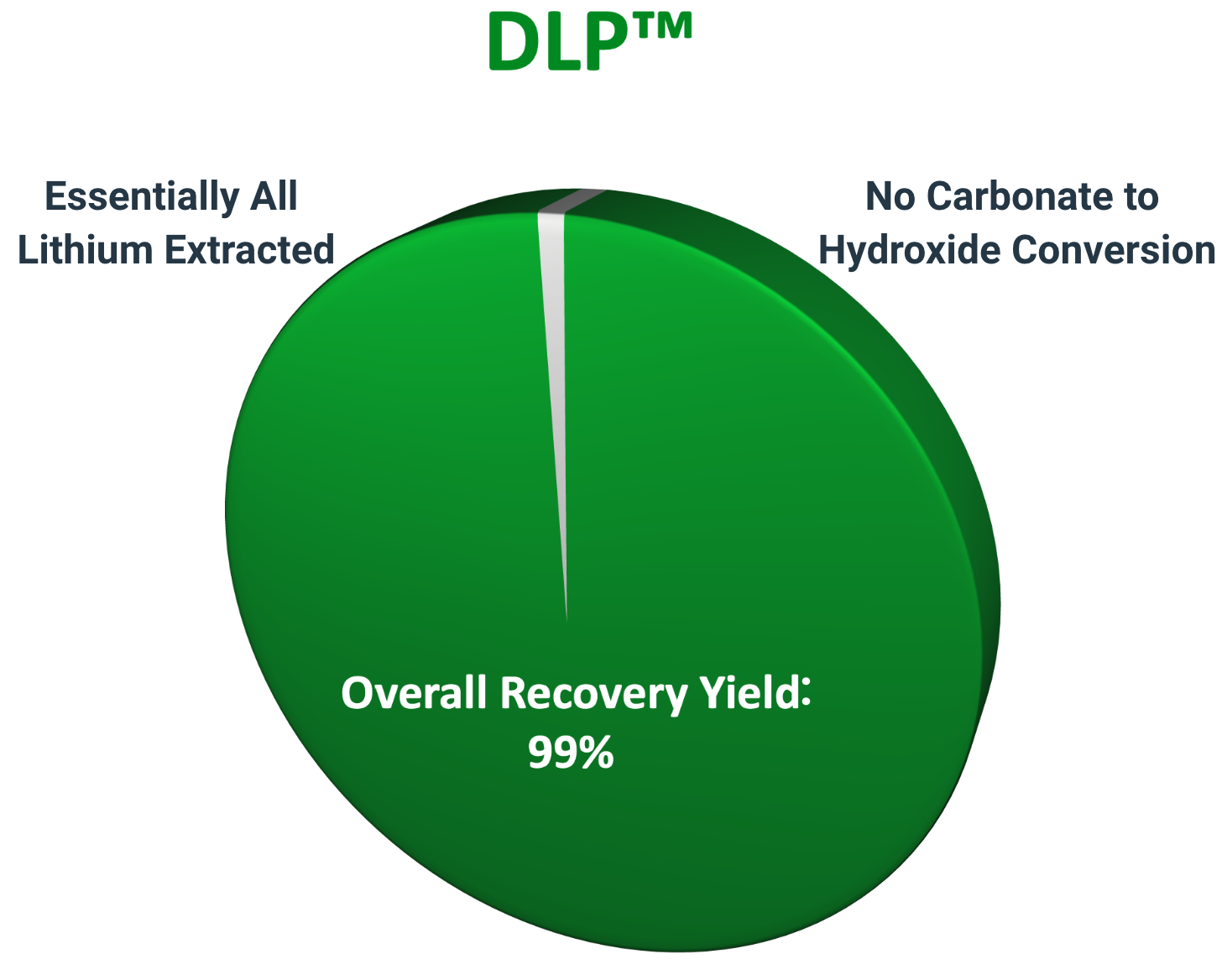

Overall Lithium Recovery

Direct Lithium to Product® (DLP™)*

- Highly selective for lithium (over Mg, Ca, Na, K and B)

- 99+% extraction yield

- Lithium hydroxide is produced directly without the extra steps of lithium carbonate production and conversion

- 99% overall recovery of lithium from brine to LiOH·H2O

- 99.5+% pure LiOH·H2O produced rapidly at the lithium extraction site

- Decreased OPEX, CAPEX and footprint due to fewer processing steps

- Essentially no water consumption: only 10 m3 per t LCE is added to the lithium depleted brine and returned to the salar, mitigating ecological damage

*Analyses for DLP™ performed by an independent 3rd party

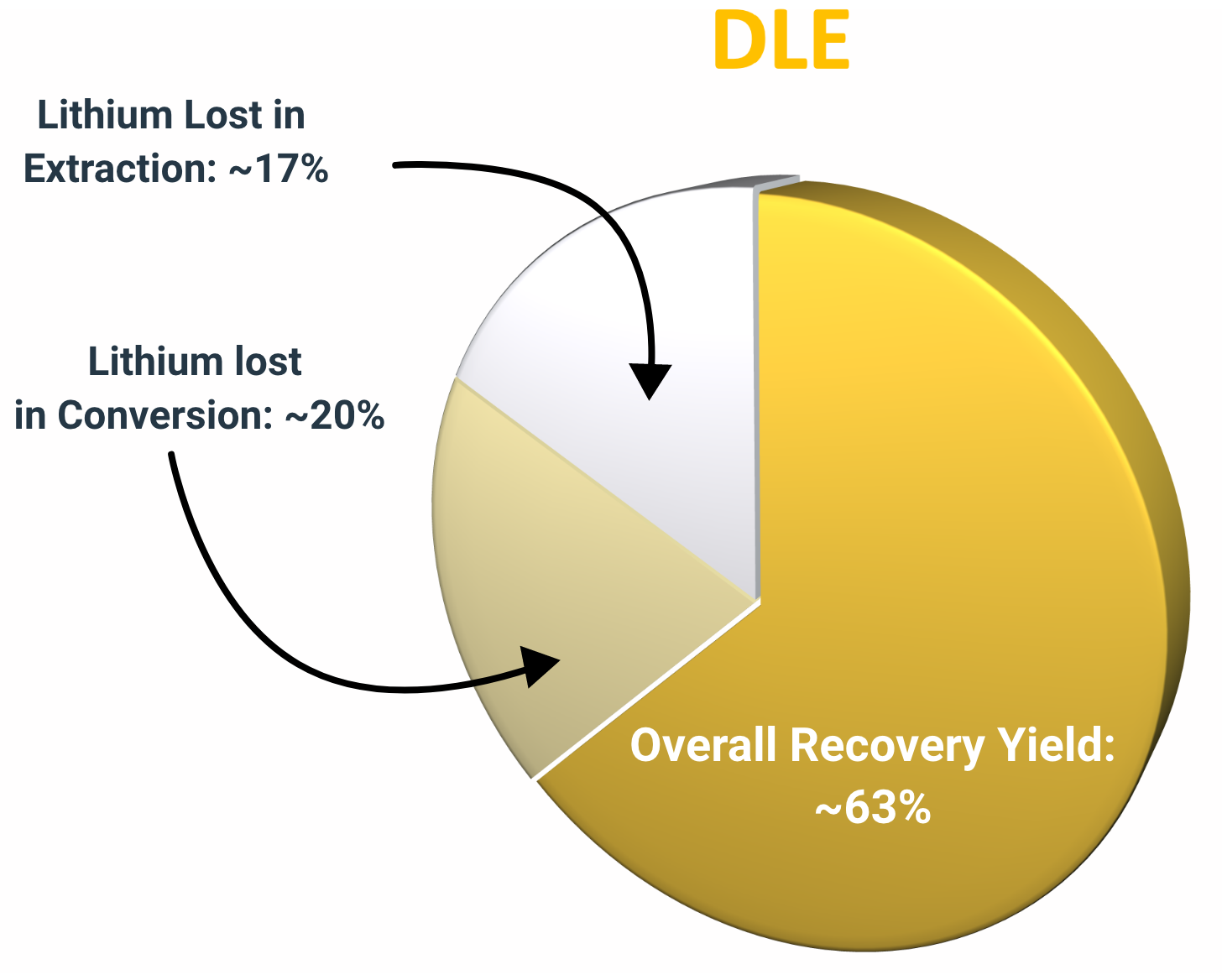

Direct Lithium Extraction (DLE)

- Pre-extraction steps required to remove impurity metals

- ~83% extraction yield

- ~20% loss of lithium in the conversion from lithium carbonate to lithium hydroxide

- ~63% overall recovery of lithium from brine to LiOH·H2O

- LiOH·H2O is not produced at the same site as lithium extraction

- Increased OPEX, CAPEX and footprint due to extra purification and conversion steps

- Moderate to high water consumption: 70-110 m3 per t LCE

*Analyses for DLP™ performed by an independent 3rd party

Sustainable Green Lithium Production

Many advantages result from the high selectivity and straightforward design of our DLP™ technology. You can save money and the environment by using the green chemistry and green engineering that is built into the GreenLiT® DLP™ process.

More Benefits of Direct Lithium to Product® (DLP™)

- Green lithium produced with very low energy consumption: 10 kWh/kg LiOH·H2O from extraction to final product

- Lithium depleted brine is returned directly to the salar with only 4% by volume of water added

- All process water is recycled

- Reagent recycling

- Minimal waste

- No harsh chemicals and no organic solvents

- No emissions